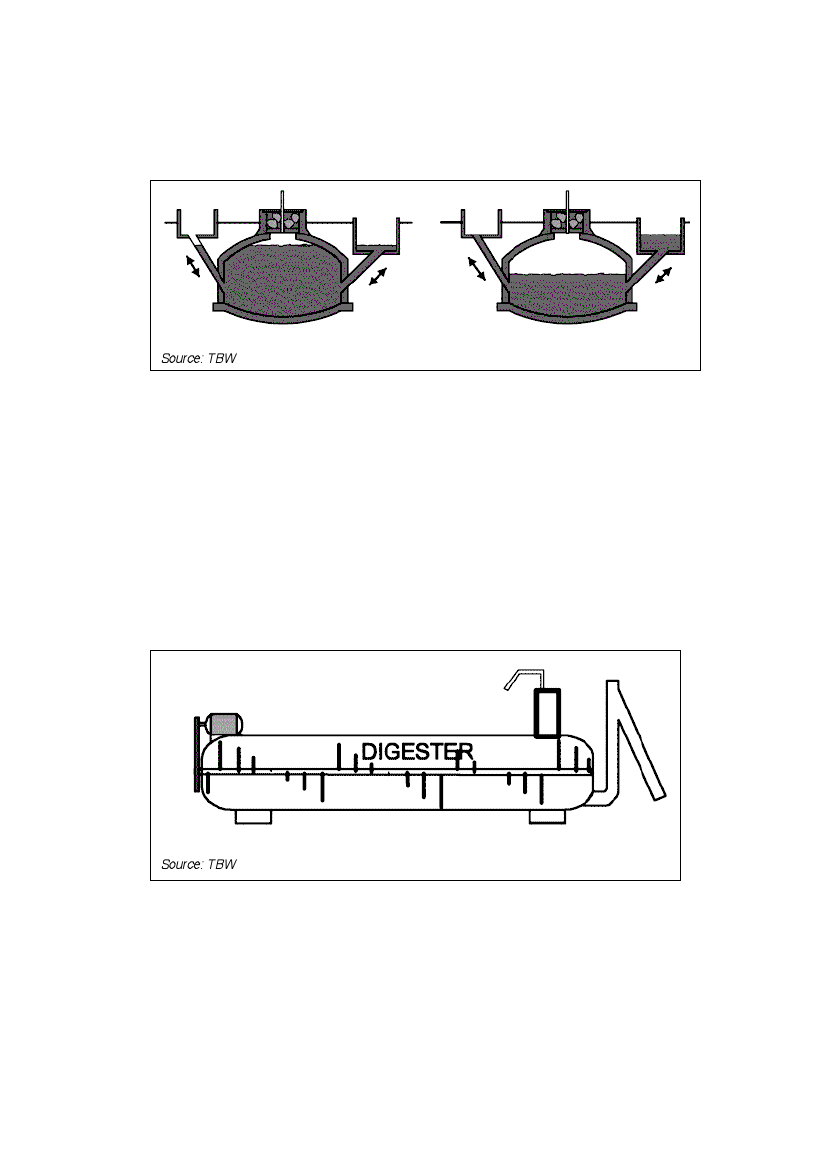

Mixing through inherent flow

In fixed dome plants, frequently found in developing countries, a certain mixing of the

substrate is provided by the substrate being pushed up in the compensation tank with gas

accumulation. When the stored gas is used, the substrate flows back into the digester.

Figure 33: Mixing of substrate through inherent flow in fixed-dome plants

Source: TBW

The company "VSP-Anlagen" further developed and patented this principle:

Through the pressure of the biogas, the substrate is pushed from the main digester into the

subsidiary digester, resulting in a difference of levels between the two digesters. By reaching

a certain difference in levels, a gas valve opens between main and subsidiary digester which

equalizes the height difference. The flow-back of the substrate is guided in a way that

destroys sinking and swimming layers.

Mechanical paddle rotor

Mechanical paddle rotors are predominantly used in horizontal steel vessels. A horizontal

shaft in hardwood bearings runs through the whole vessel. Attached are paddles or loop-

shaped pipes. By turning the shaft the vessel contents are mixed, the swimming layer is

broken up and sediments are pushed towards a drainage opening. The loop-shaped pipes

can also be used as heat exchangers to warm up the substrate.

Figure 34: Mechanical paddle rotor

Source: TBW

Submerged motor with rotor stirring

A sealed, submerged electric engine directly drives a rotor. The rotor mixes the substrate by

creating a strong current. These stirring devices can usually be adjusted in height and in

angle.

56